* Series 8100

Floating Ball Valve

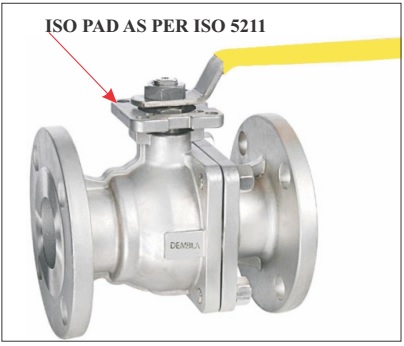

These Valves Are Simple In Design And Seat Guided. Both Soft And Metal To Metal Seated Available. Live Loaded Packing, Anti Static Device, Blow Out Proof Stem, Locking Device, Integral Mounting Pad In Accordance With ISO 5211 Are Standard Features.

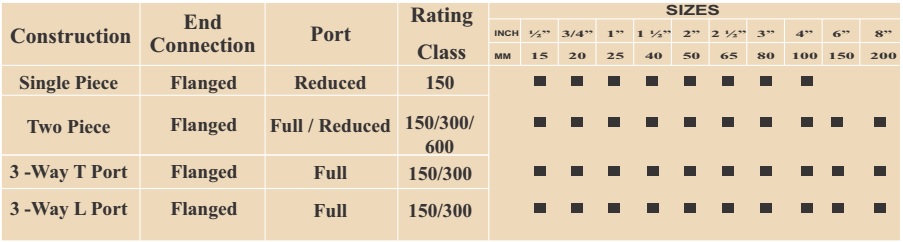

Product Range

Features

• Live Loaded Gland Packing

Graphite Packing are provided as standard taking care of Fire Safe Design Condition. Belleville Springs Washers are used to achieve live loading which protects Gland loosening under vibrations & shock conditions.

• Antistatic Device

To ensure Electrical Continuity between the Stem and Ball and Body all Valves are provided with

Antistatic device as an integral part of Floating Ball Valves.

• Blow Out Proof Stem

Stem is Designed to include a collar to provide protection against Blow Outs.

• Double ‘D’ Stem to Lever Connection

Stems are Designed to have Double ‘D’ Connection at the top for Lever Fixing. This feature eliminates possibility of Lever Assembly in the wrong direction as the Lever indicates the Valve Position once. installed on the line.

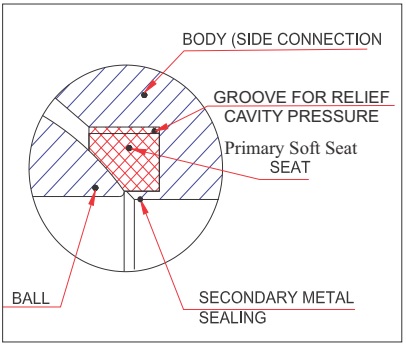

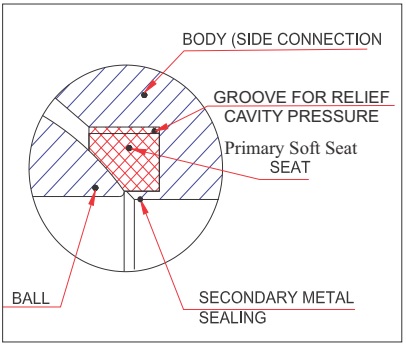

• Equalized Cavity Pressure

The Pressure equalization hole at the top of the Ball combined with Seat Design are Engineered to

maintain the Pressure balance in the line & in the Body Cavity irrespective of Valve Position.

• Locking Device

Locking devices are provided on all Valves with both Lever Operator ad Gear Operator.

DESIGN FEATURES

STEAM SEAL

We Provide multiple stem sealing for high degree of sealing

FIRE SAFE

Fire Safe Design as per API 607, API 6FA

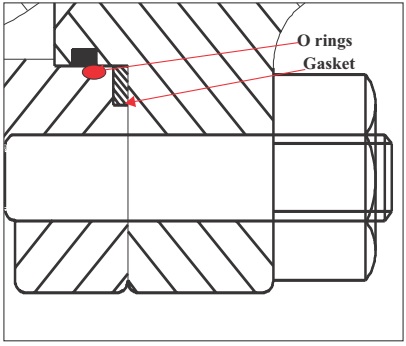

BODY SEALING

We Provide O ring & Gasket between body

and side connection for effective sealing.

ISO PAD

We provide mouting pad for actuator gear

operated mouting as per ISO 5211

Some line fluid is usually left trapped inside the ball-body cavity. This fluid can expand under the influenceof high ambient and line temperature. An abnormal increase of such cavity pressure may sometimes damage the valve seats or balls, unless the valve has an adequate cavity pressure relief provision. General solution for floating ball valve is to provide hole in the ball-stem slot to equalize the pressure behind the valve cavity.

In floating ball valves the line pressure forces the ball to the downstream seat, the seat flexes and creates the seal. The upstream seat is forced forward, allowing the pressure to penetrate from behind through the grooves and into the body cavity, which relieving the load and prevent the seat damage.

FOR MORE INFORMATION ABOUT PRODUCT

CLICK LINK BELOW

CATALOGUE.PDF