Diaphragm Valves Product List

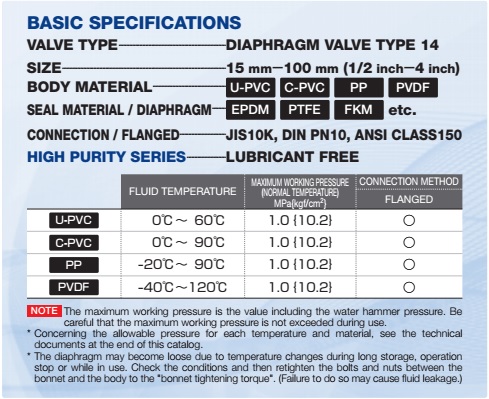

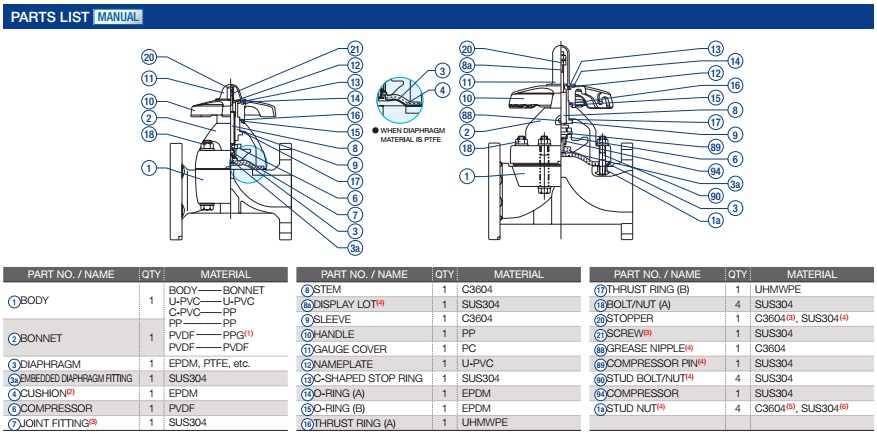

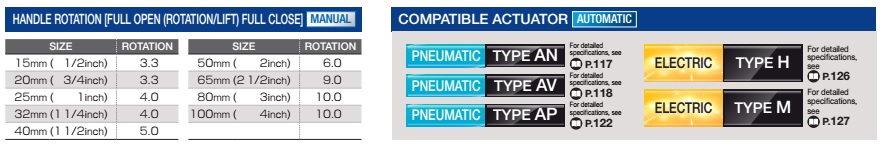

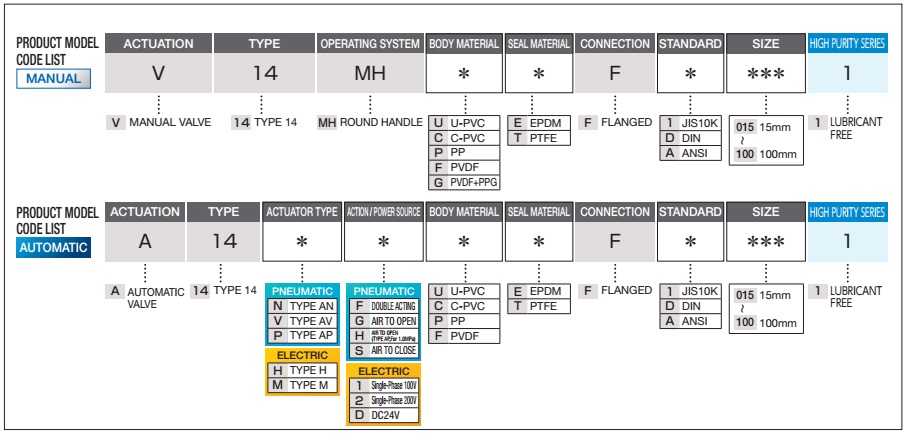

1. DIAPHRAGM VALVE TYPE 14 (15-100mm)[1/2-4inch]

• Excellent Sealing Property

The DIAPHRAGM VALVE TYPE 14 uses a high quality rubber material,exhibiting lower compressive strain, for its diaphragm and cushion,resulting in optimum sealing performance.

• Tight Seal at Low Torque

Using dynamic analysis by CAE, DIAPHRAGM VALVE TYPE 14 is designed so that pressure is distributed evenly.This design allows the hand wheel torque be reduced and maintain shutt off at low torque.

• Easier Maintenance

A bayonet mechanism, provided between the diaphragm and compressor, allows the diaphragm to be replaced easily.

• Bottom Stand for Easy Support

Having a new bottom stand with an insert hole, DIAPHRAGM VALVE TYPE 14 helps support the piping. The valve is also provided with a flange stand to increase installation safety.

• Built-in Travel Stop

DIAPHRAGM VALVE TYPE 14 contains a revolutionary travel stop mechanism protecting the diaphragm.

• Visual Indicator

A color indicator clearly shows whether the valve is fully open, half open, or fully closed. Because the indicator enters the handle,going out of view when the valve fully closes, the operator can know at glance valve position.

• NEAR-LINEAR FLOW CHARACTERISTICS

• A NEW TYPE OF RUBBER HAVING A HIGH RELIABILITY IN LEAKAGE PREVENTION IS

USED FOR THE DIAPHRAGM AND CUSHION.

• THE ORIGINAL DESIGN ACHIEVES HIGH SEALING PERFORMANCE WITH LOW

TORQUE.

• BAYONET STRUCTURE ALLOWING QUICK DIAPHRAGM REPLACEMENT

• EQUIPPED WITH A BOTTOM STAND ALLOWING EASY ADN SECURE REPLACEMENT.

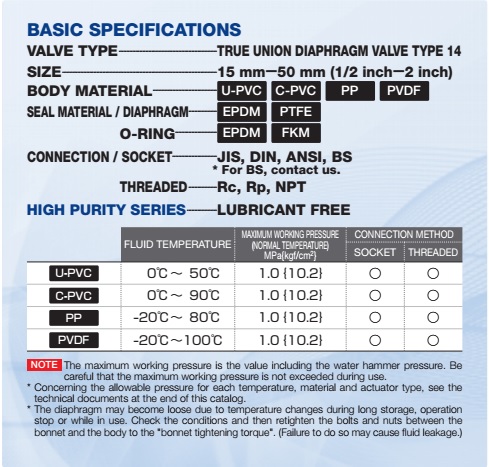

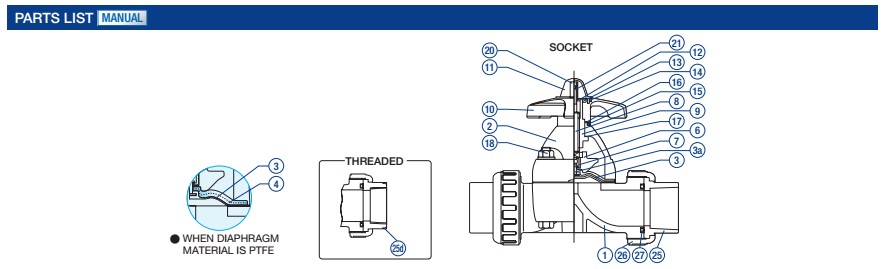

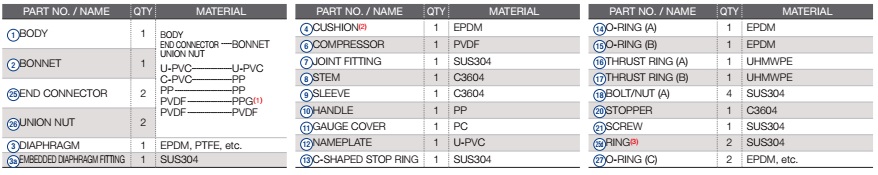

2. TRUE UNION DIAPHRAGM VALVE TYPE 14(15-50mm)[1/2-2inch]

• Easy Maintenance

The valve body can be removed from the pipe line by loosening the union nuts at both its ends.

• Bottom Stand for Easy Support

Having a new bottom stand with an insert hole, DIAPHRAGM VALVE TYPE 14 helps support the piping. The valve is also provided with a flange stand to increase installation safety.

• NEAR-LINEAR FLOW CHARACTERISTICS

• NEWLY EQUIPPED WITH BOTTOM STAND WITH INSERT HOLE TO ENSURE EASY AND

SECURE INSTALLATION

• THE VALVE BODY CAN BE REMOVED FROM THE LINE

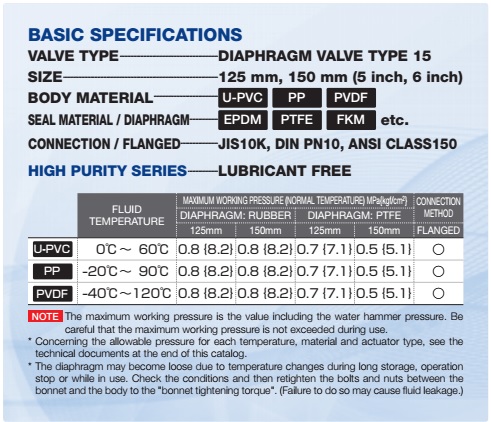

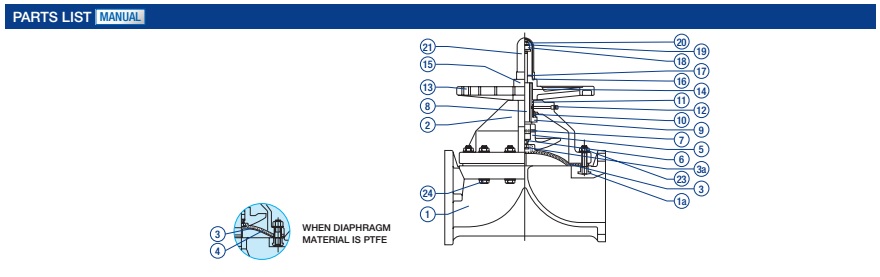

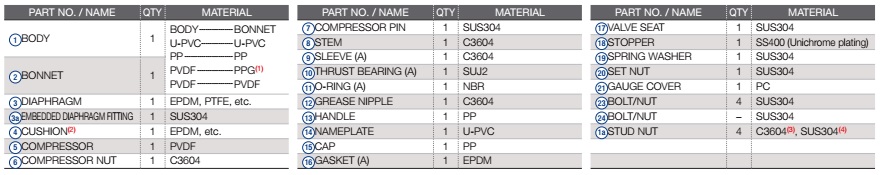

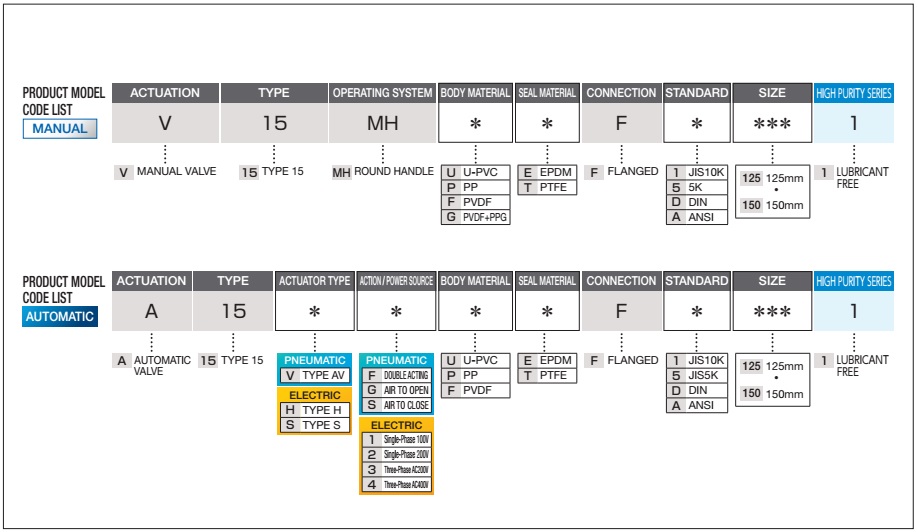

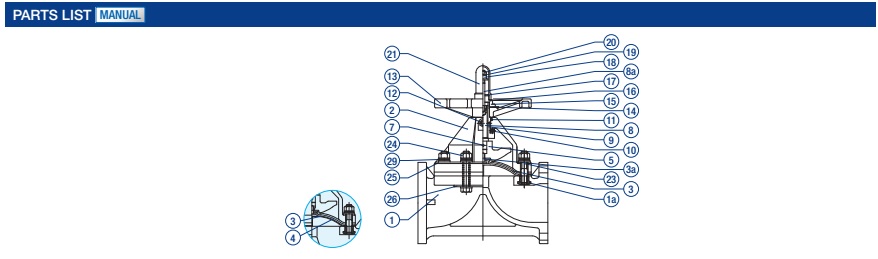

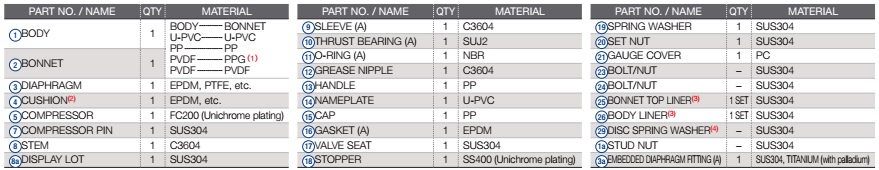

3. DIAPHRAGM VALVE TYPE 15(125,150mm)[5,6inch]

• Improved outside sealing ability

By means of 3D CAD/CAE analysis, Type 15 diaphragm valve has increased body thickness. ln addition, usnig the elastomer that has high impact resilience, the sealing ability of valve is improved against high temperature changes.

• Easier to operate

In order to reduce frictional force, material and shape of sliding parts are redesigned. Also improved hand wheel design allows for easy operation.

• NEAR-LINEAR CHARACTERISTICS

• REQUIRES LESS HANDLE OPERATION FORCE THANKS TO IMPROVED MATERIAL AND

SHAPE.

• THE GAUGE COVER ALSO SERVES AS AN INDICATOR, ALLOWING EASY CHECK OF

OPENING DEGREE.

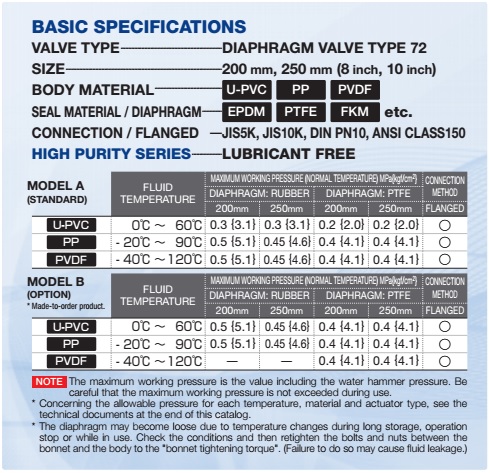

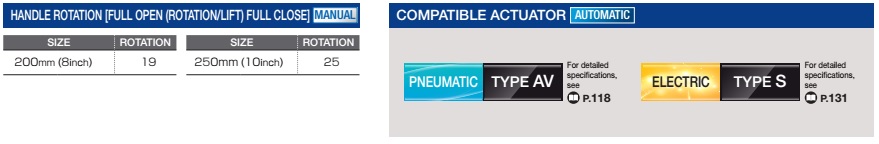

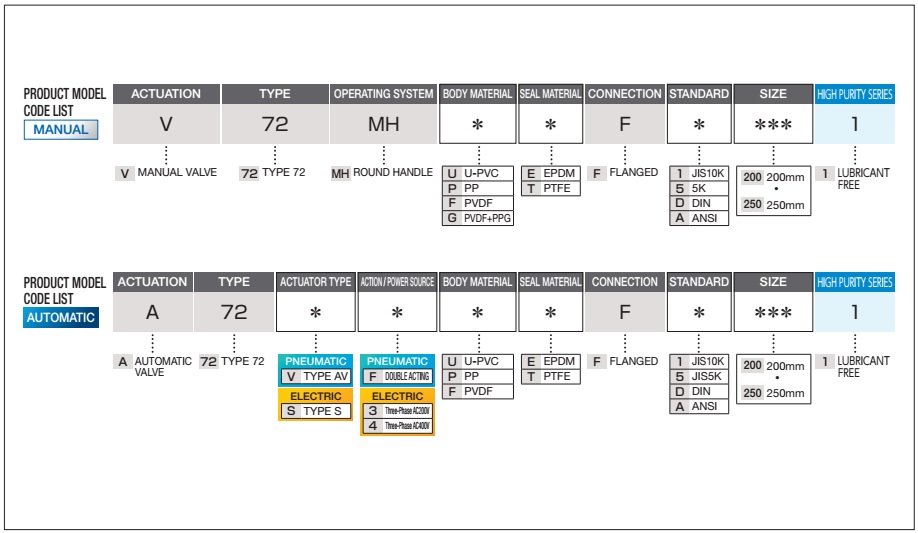

4. DIAPHRAGM VALVE TYPE 72(200,250mm)[8,10inch]

• Sealed Bonnet

Having a sealed bonnet with an O-ring, prevents rain water or external atmosphere from entering the bonnet, DIAPHRAGM VALVE TYPE 72 can be safelly used outdoors.

• Sealed Indicator

Because a clear indicator gauge protects the exposed metallic part on top of the stem against atmosphere, corrosive gas or fluid does not of the valve.

• Position Indication

The position indicator also shows the degree of the valve position.

• NEAR-LINEAR FLOW CHARACTERISTICS

• TRANSPARENT GAUGE COVER (MADE OF POLYCARBONATE) PROTECTS THE

INTERNAL AND EXTERNAL PARTS FROM CORROSIVE CHEMICAL SOLUTIONS AND

GASES.

• THE GAUGE COVER ALSO SERVES AS AN INDICATOR, ALLOWING EASY CHECK OF

OPENING DEGREE.

5. DIAPHRAGM VALVE / Chlor-Alkali Specification & EL Specification

The detail of EL-Specification

Feature:To prevent the generation of blister and crack by applying special material.

Medium:High temperature brine, Sodium hypochlorite, Hydrofluoric acid and so on.

Countermeasure:for blister, crack, peeling-off and so on.

Parts:EL-PVDF(Body) and EL-PTFE(Diaphragm)

Target:Chlor/Alkali industry, pulp & paper industry, steel industry and so on.

Reference:Many factories especially in Electrolysis plants in world wide.

Size : 15mm(1/2inch) - 100mm(4inch).

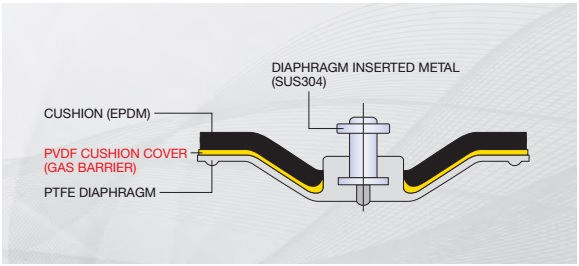

For corrosive fluid transport lines,

we offer PVDF

cushion cover accessories having excellent

gas barrier performance to prevent deterioration

due to permeation of gas from the diaphragm.

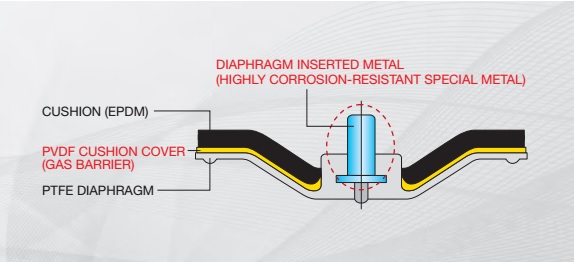

For chlorine gas lines in electrolysis plants, we

offer electrolytic options using highly corrosion

resistant special metal to prevent corrosion of

embedded diaphragm fittings.

FOR MORE INFORMATION ABOUT THE PRODUCT

PLEASE CLICK LINK BELOW

CATALOG.PDF