½” - 8” | Class 150 - Class 300

DN 15 - DN 200 | PN 16 - PN 40

JC offers also a large range of metal seated ball valves for different services (slurries, pulp and liquors, high temperature, abrasive or sticking fluids, control).

• Bubble tight sealing up to 327 ºC and Class V up to 500 ºC

• Low coefficient of friction

• Excellent sliding and running properties

• Hardens the complete surface of ball and seats

WHY METAL SEATED BALL VALVES?

Metal seated ball valves are mainly used for heavy duty applications such as:

• High temperatures: above 260 ºC the use of soft seats is not recommended.

• Abrassive media: even small particles can damage soft seats.

• High Velocity in opening/closing cycles: this action can perfectly deform the soft ring and

destroy the seat.

HARDERING TREATMENTS

HT-65

Max. Temperature: 500 ºC

Corrosion Resistance: Medium

Abrasion Resistance: Medium

This is an exclusive treatment developed by JC with two main advantages, first all the ball and seat surface is hardened and second there is no additional overlay on the seat surface. This gives a very good tightness and a lower torque. The surface is hardened to 70 Rockwell C and it is valid to work upto 500 ºC.

CT-70

Max. Temperature: 550 ºC

Corrosion Resistance: Medium

Abrasion Resistance: High

Is a Tungsten Carbide coating in a metallic matrix bonded. Mechanically to the base material by HVOF methods. This treatment gives a very good resistance to abrasion and impact and is suitable to work upon 550 ºC.

CC-60

Max. Temperature: 800 ºC

Corrosion Resistance: High

Abrasion Resistance: High

Is a Chromium Carbide coating in a nickel-chrome base in a metallic matrix bonded mechanically to the base material by HVOF methods. This treatment gives a very good resistance to abrasion and is the best choice for severe corrosion applications. It is suitable to work up to 800 ºC.

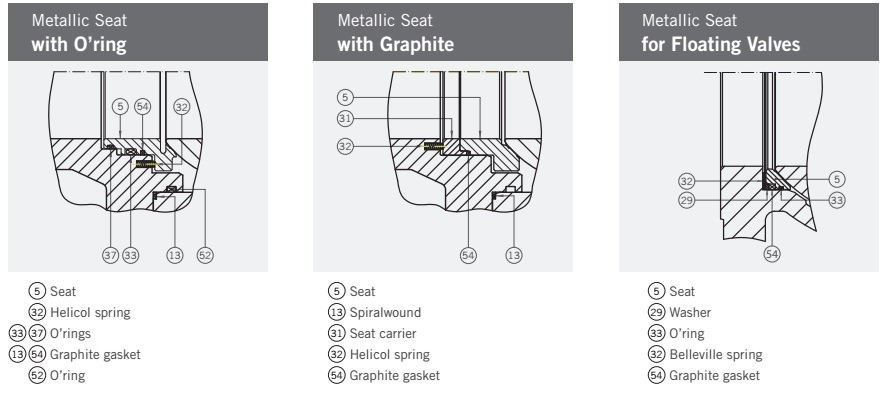

DIFFERENT SEAT DESIGNS

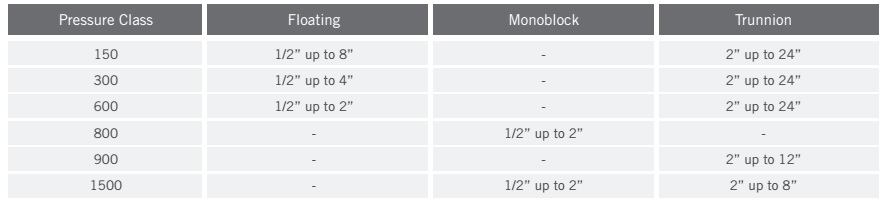

RANGE OF METAL SEATED BALL VALVES

JC can produce the following metal seated ball valves:

PRODUCTION OF METAL SEATED BALL VALVES

Metal seated ball valves are mainly used for heavy duty applications.

One of the main advantages of using JC metal seated ball valves is the fact that we can transform a soft seated stock valves into a metal seated valve.

The steps to be done are:

• Re-machining of the body.

• Lapping of the ball and seats.

• Hardening treatment to ball and seats.

• Final adjustment of the ball with its seats.

• Assembly and test.

• EN-DIN 3516 / 3540

PRODUCT RANGE

3516: PN 16 from DN 65 to DN 200

3540: PN 40 from DN 15 to DN 150

MATERIALS

BODY: Carbon steel, Stainless steel, Low temperature carbon steel, Duplex, Special Alloys,... Other materials under request

SEATS : A182 F316 or A351Gr. CF8M. Other materials under request

TRIM: 316, 410, MONEL,... Other materials under request

STANDARD'S

• PED

• Quality Standard MSS SP 55

• All wetted component materials meet NACE MR0175 / ISO15156 & NACE MR0103 /

ISO17945

• Fire-Safe API 607, ISO 10497

• Fugitive Emissions : ISO 15848 / TA-LUFT

• ATEX

DESIGN FEATURE

• Split body, full bore. Fire-Safe design (soft seated construction Fire-Safe certified), floating

ball, blow out proof stem, flanged connections.

• Non-removable antistatic devices assure electric continuity between ball and

body through the stem.

• Cavity pressure balancing hole avoids overpressure in the cavity with the valve

in open position.

• Asbestos free.

• CE and ATEX marked.

APPLICATION

• Refinery

• Chemical

• Petrochemical

• Power plant

• Gas

• ASME 3515 / 3530

PRODUCT RANGE

3515: Class 150 from ½'' to 8''

3530: Class 300 from ½'' to 6''

MATERIALS

BODY: Carbon steel, Stainless steel, Low temperature carbon steel, Duplex, Special Alloys,... Other materials under request

SEATS : A182 F316 or A351Gr. CF8M. Other materials under request

TRIM: 316, 410, MONEL,... Other materials under request

DESIGN FEATURE

Split body, full bore. Fire-Safe design (soft seated construction Fire-Safe certified), floating ball, blow out proof stem, flanged connections.

Non-removable antistatic devices assure electric continuity between ball and

body through the stem.

Cavity pressure balancing hole avoids overpressure in the cavity with the valve

in open position.

Asbestos free.

CE and ATEX marked.

APPLICATION

Refinery

Chemical

Petrochemical

Power plant

Gas