FLOATING ASME

3/8” - 12” | Class 150 - Class 600

A floating ball valve is a valve with seats supported ball, that is pushed by upstream pressure towards the downstream seat to ensure sealing. The DN of the floating ball valves range is limited by the capability of the seats material to support the pressure, temperature and weight of the ball.

• 515 / 530 FB

PRODUCT RANGE

515: Class 150 from ½'' to 8''

530: Class 300 from ½'' to 6''

MATERIALS

BODY: Carbon steel, Stainless steel, Low temperature carbon steel, Duplex, Special Alloys,... Other materials under request

SEATS : PTFE, RPTFE, PEEK, DEVLON, NYLON,... Other materials under request

TRIM: 316, 410, MONEL,... Other materials under request

STANDARDS

• API 6D

• PED

• Quality Standard MSS SP 55

• All wetted component materials meet NACE MR0175 / ISO15156 & NACE MR0103 / • ISO17945

• Fire-Safe API 607, ISO 10497, API 6FA

• Fugitive Emissions : ISO 15848 / TA-LUFT

• ATEX

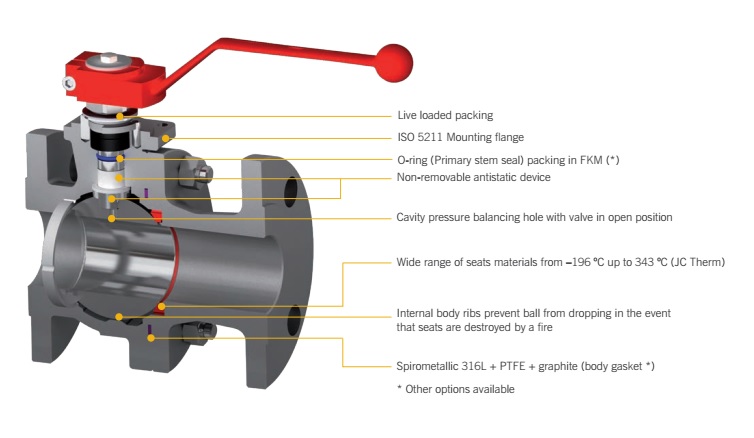

DESIGN FEATURE

• Split body, full bore. Fire-Safe certified, floating ball, blow out proof stem, flanged

connections.

• Non-removable antistatic devices assure electric continuity between ball and body through

the stem.

• All wetted component materials and bolting meet NACE MR.01.75 latest edition as

standard.

• Cavity pressure balancing hole avoids overpressure in the cavity with the valve in open

position.

• Asbestos free.

• CE and ATEX marked.

APPLICATION

Refinery

Chemical

Petrochemical

Power plant

Gas

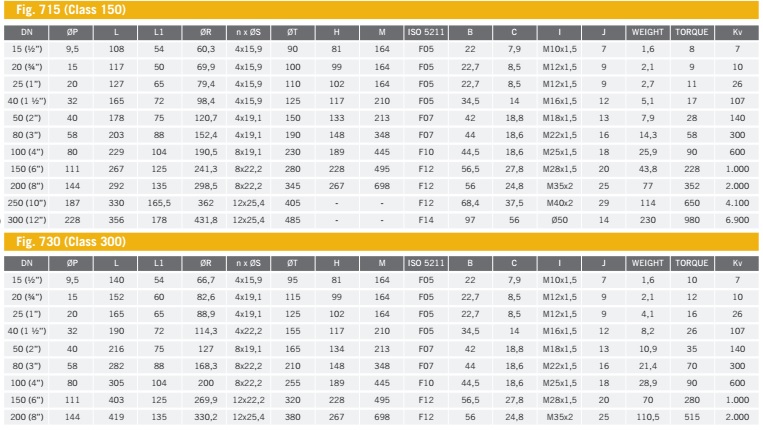

• 715 / 730 RB

PRODUCT RANGE

• 715: Class 150 from ½'' to 12''

• 730: Class 300 from ½'' to 8''

CHARACTERISTIC

• End entry, reduced bore

• Flanged connection

• Non-ejection shaft

• Antistatic device

• Balancing bore in ball

• “Live Loaded” packing

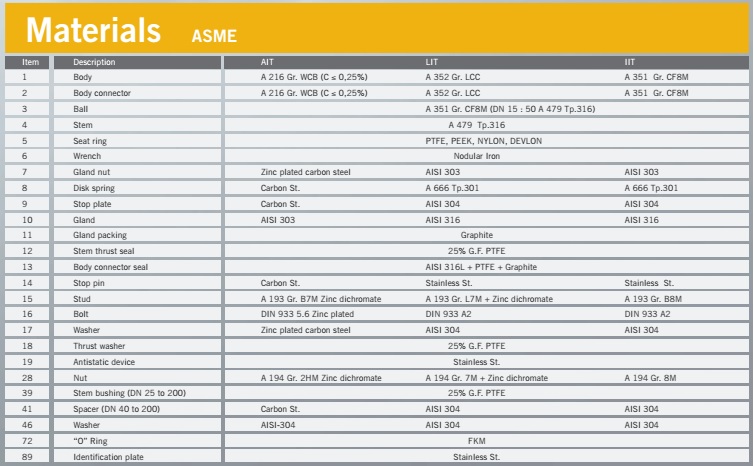

MATERIALS

BODY: Carbon steel, Stainless steel, Low temperature carbon steel, Duplex, Special Alloys,... Other materials under request

SEATS : PTFE, RPTFE, PEEK, DEVLON, NYLON,... Other materials under request

TRIM: 316, 410, MONEL,... Other materials under request

DESIGN FEATURE

• End entry, reduced bore. Fire-Safe certified, floating ball, blow out proof stem, flanged

connections.

• Non-removable antistatic devices assure electric continuity between ball and body through

the stem.

• All wetted component materials meet NACE MR.01.75 latest edition as standard.

• Cavity pressure balancing hole avoids overpressure in the cavity with the valve in open

position.

• Asbestos free.

• CE and ATEX marked.

APPLICATION

• Refinery

• Chemical

• Petrochemical

• Power plant

• Gas

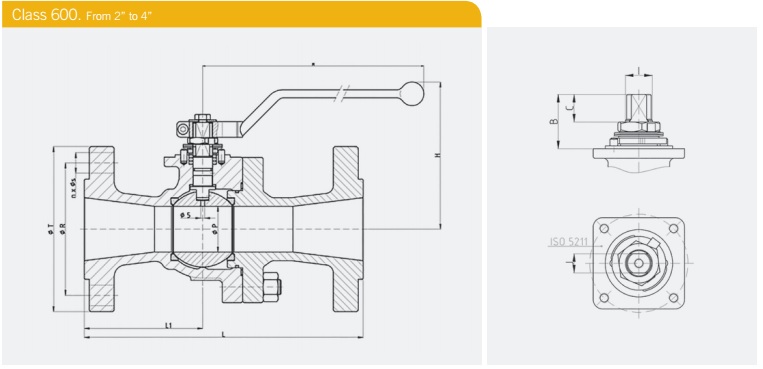

• 560 FB

PRODUCT RANGE

560: Class 600 from 2'' to 4''

MATERIALS

BODY: Carbon steel, Stainless steel, Low temperature carbon steel, Duplex, Special Alloys,... Other materials under request

SEATS : PTFE, RPTFE, PEEK, DEVLON, NYLON,... Other materials under request

TRIM: 316, 410, MONEL,... Other materials under request

DESIGN FEATURE

Split body, full bore. Fire-Safe certified, floating ball, blow out proof stem, flanged connections.

Non-removable antistatic devices assure electric continuity between ball and body through the stem.

All wetted component materials and bolting meet NACE MR.01.75 latest edition as standard.

Cavity pressure balancing hole avoids overpressure in the cavity with the valve in open position.

Asbestos free.

CE and ATEX marked.

APPLICATION

Refinery

Chemical

Petrochemical

Power plant

Gas

• 660 RB

PRODUCT RANGE

660: Class 600 from 2'' to 4''

PRODUCT FEATURES

• Split body, Reduced bore

• Flanged connections

• Blowout-proof stem

• Non-removable antistatic devices

• Cavity pressure balancing hole

• Live Loaded Packing

MATERIALS

BODY: Carbon steel, Stainless steel, Low temperature carbon steel, Duplex, Special Alloys,... Other materials under request

SEATS : PTFE, RPTFE, PEEK, DEVLON, NYLON,... Other materials under request

TRIM: 316, 410, MONEL,... Other materials under reques

DESIGN STANDARDS

• API 6D• PED

• Quality Standard MSS SP 55

• All wetted component materials meet NACE MR0175 / ISO15156 & NACE MR0103 /

ISO17945

• Fire-Safe API 607, ISO 10497, API 6FA

• Fugitive Emissions : ISO 15848 / TA-LUFT

DESIGN FEATURE

• Split body, reduced bore. Fire-Safe certified, floating ball, blow out proof stem, flanged

connections.

• Non-removable antistatic devices assure electric continuity between ball and body through

the stem.

• All wetted component materials and bolting meet NACE MR.01.75 latest edition as

standard.

• Cavity pressure balancing hole avoids overpressure in the cavity with the valve in open

position.

• Asbestos free.

• CE and ATEX marked.

APPLICATION

Refinery

Chemical

Petrochemical

Power plant

Gas