Plate Heat Exchangers (PHE)

Plate Heat Exchangers (PHE) are heat exchangers made of thin sheets of corrosion resistant metals compressed in between two metal frames. The function of a Plate heat exchanger is to cool down or heat up a particular flowing liquid. This is done by applying thermodynamics concepts to transfer heat from two counter current flowing liquids of different temperatures.

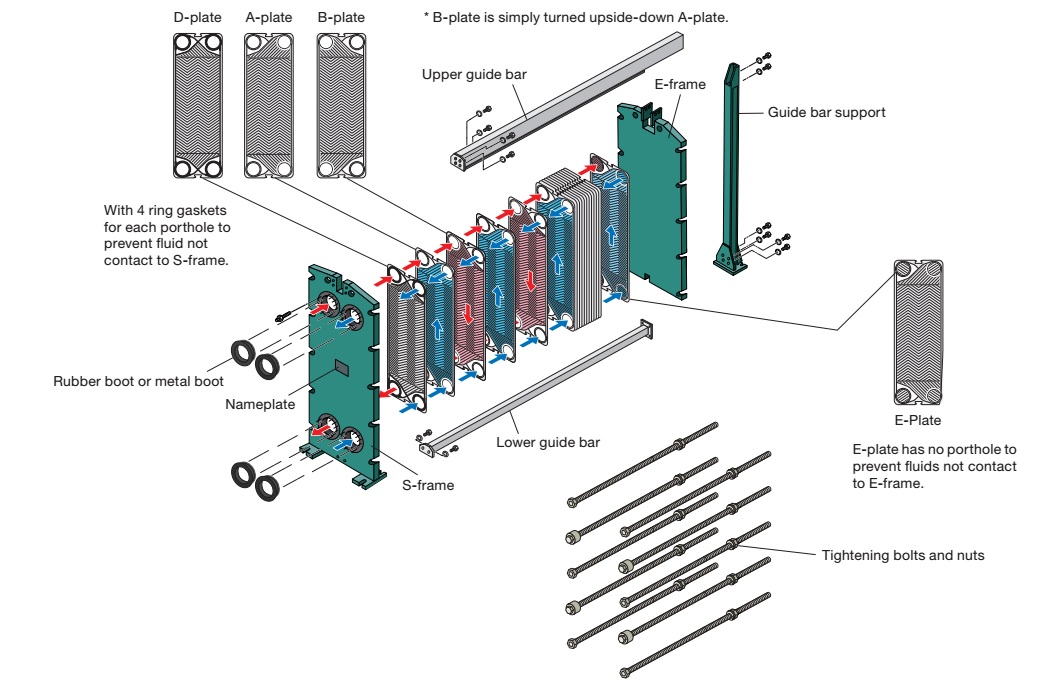

External Structure

The heat transfer Plates are made of thin sheets of corrosion resistant metals such as stainless steel or titanium that are press-formed with a corrugated pattern on the surface and sealed with synthetic rubber gaskets, which seals the flow channel and directs the fluid into alternate channels. Such Plates are suspended, supported and aligned by guide bars and are tightened with bolts between a fixed and a moveable frame. The overall heat duty can be adjusted by modifying the number of heat exchanging Plates.

BASIC STRUCTURE

Heat transfer plates are made by pressing thin sheets of corrosion-resis- tant metal such as stainless steel or titanium, then set them with seal gaskets and hang and pile them on the guide bar. Then, plates are tightened with bolts between the fixed frame and the movable frame. Here, there is a certain gap between the heat transfer plates that allows liquid to flow. The liquid inlets and outlets are in the fixed

frame or the movable frame.

HEAT TRANSFER PLATE

Each heat transfer plate is corrugated to various patterns to increase its strength and surface area. Furthermore, the corrugation makes high turbulence and thereby achieves high heat transfer coefficient. Portholes are formed in the plate's four corners. The gasket is set into the groove around the plate edge to seal in the Fluid.

STRUCTURE OF A PLATE HEAT EXCHANGER

FEATURES

• High Performance

The overall heat transfer co-efficient (U-value) ranges from 4,000 to 9,000 W/m2 · °C in water application, since the plate corrugation provides a highly turbulent flow. This is one of the reasons why plate heat exchangers have such a high heat transfer coeffi- cient. In addition, this turbulent flow also acts to prevent scales on the plate surface.

• Easy Maintenance

Loosening the tightening bolts allows for simple disassembly. The heat transfer plates can be easily inspected visually, and cleaning is easy.

• Steam available as the heat source

The use of a synthetic rubber gasket with a special composition enables the use of steam as a heat source, that is, an operating temperature range up to 180°C.

• Minimal Heat radiation

Heat radiation from plate pack is blocked by the gasket, with only a minimal amount of heat radiation from the thin Fin-shaped edge. Also, as the front and rear of plate pack is connected to the frame of each through an air layer, the heat radiation is minimal. Except in cases with an extremely small number of plates, it is less than 1% of the heat exchange amount.

MORE INFORMATION ABOUT PRODUCT

PLEASE CLICK LINK BELOW