Alumite Processes

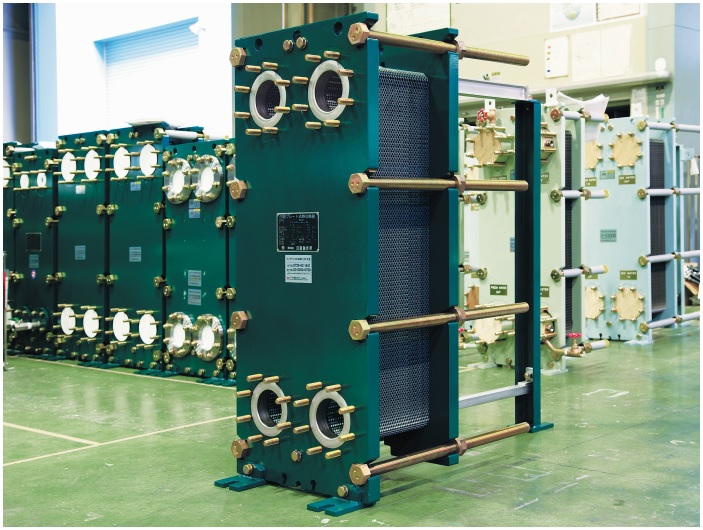

HISAKA PHEs - An ideal for Alumite Processes with its high Performance, Process Alteration Flexibility and Corrosion Resistance Properties.

Alumunium is a soft metal that is very prone to scratches and environmental damage. Hence, processing alumunium and its alloy parts increases its strength and durability against corrosion and weather damage. Processed aluminium is known as Alumite; a technology developed in Japan by forming an aluminium oxide film on the aluminium (or its alloy) surface.

The oxygen produced at the anode (positive pole) will produce a porous layer with great electical isolation characteristics to improve on :

a. Corrosion resistance

b. Water resistance

c. Heat absorbance

d. Optical reflection

e. Coloration properties

Therefore, alumite is suitable to be used in various contemporary industries such as:

* Construction materials * Printed Wiring Boards

* Automotive components * Electrolytic condensers

* Optical device components * Reflector panels

* Solar heat absorbent panels * Magnetic storage disks

HISAKA plate heat exchanger (PHE) is ideal for alumite processing is because of its high performing and high alteration flexibility to correspond to specific processes, especially when highly corrosive solutions such as sulfuric acids and oxalic acids are involved. Furthermore, the usage of HISAKA PHE is vast in the alumite production process, of which including:

i) Heating of degreasing solutions

ii) Heating of etching solutions

iii) Heating of sulfuric acid solutions

iv) Cooling of alumite solutions

For more information, kindly Click Here