Structure of Brazed Plate Heat Exchanger (BHE)

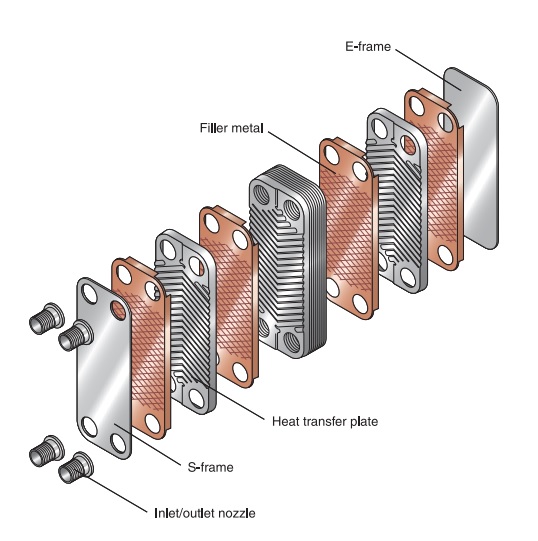

With a Simple structure made up of just heat transfer plates, an E-frame and an S-frame that reinforce those plates, and inlet/outlet nozzles that guide the fluids in and out of the exchanger - all made of stainless steel - the BHE uses few materials and so can be produced in high volumes.

Compared to other welding methods, with a low heating temperature for bonding and good workability mean that it can bond thin plates and parts that are required precision. Because the filler metal penetrates into gapz, brazing can be used for bonding complex-shape parts and for multipoint bonds. With Certain bonding designs, brazing can provide bonds of strength equaling or higher than that of the base materials.

It has now become indispensable not only for ordinary industrial products but also for industries on the cutting edge electronics, aeronautics and the space industry.

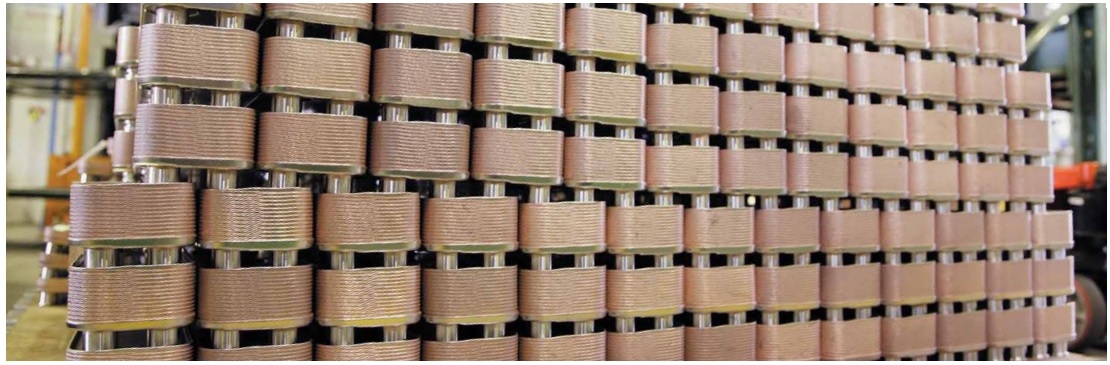

BHE are created by layering stainless steel plates and a brazing material such as copper or nickel and then heating the brazing material to a temperature exceeding 1100°C in a vacuum furnace prior melting the brazing material to solidify and integrate the plates with one and another.

Features of Brazed Plate Heat Exchanger

♦ High Performance

The unique herringbone plates pattern enhances the heat transfer performance and ultimately providing a higher heat transfer rate even with a smaller heat transfer area as compared to shell and tube heat exchangers.

♦ Excellent heat and pressure resistance

The tough gasket-less brazed structure enables a high sealing performance, excellent pressure resistance and not to mention high heat and cold resistance.

♦ Light and Compact

The brazed structure enables thinner materials to be used, allowing the structure to be more compact and lighter as compare to a shell and tube heat exchanger of similar capacity. Additionally, BHE structure is more compact and lighter than PHE.

♦ Excellent economy

With constant economical pursues, low price can be obtained with mass production as well as reducing the components to the absolute minimum.

♦ Close proximity of fluid temperature difference

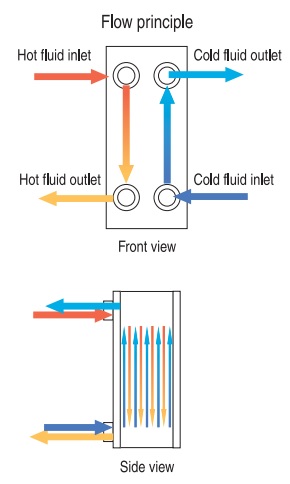

The construction of BHE permits heat exchange under perfect counter current flow with very high heat transfer efficiencies. Consequently, this feature enables the utilization of fluids with a temperature difference as close as 1°C or lesser.

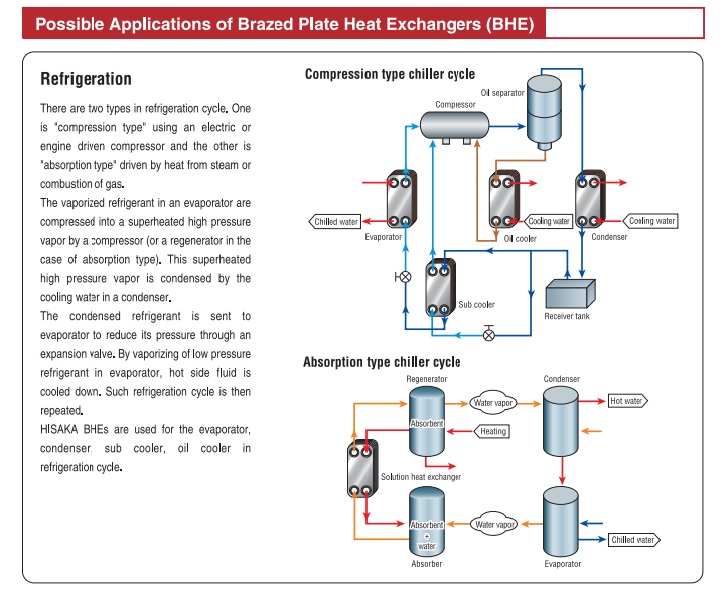

Braze plate Heat Exchanger (BHE) retains the high economy and performance of "Gasketed plate heat exchanger", while adding even greater lightness, compactness, durability and economy by brazed construction. BHE can also be used with refrigerant such as ammonia and Freon due to the above features.

FOR MORE INFORMATION ABOUT THE PRODUCT

PLEASE CLICK LINK BELOW

CATALOG.PDF