SPIRAL HEAT EXCHANGER

KUROSE SPIRAL HEAT (KSH)

SPIRAL HEAT EXCHANGER

-

- Summary : spiral heat exchanger is known as the best heating device for the purpose of energy saving as compared to the conventional heat exchangers. High heat transfer rates is avaible due to the fluid passes through the spiral type channels in completely counter current. It is almost clean without scale forming during performance and apperas same flowing manner in both sides of channels which is different from the tubeside and shellside flow of tubullar type Heat exchanger. Therefore, Spyraltype heat exchanger is suitablle for the fluids in case of difficulties of cleaning, Moreover, as for the same heat transfer capacity is concerned. It is more compact and easy for installation than that of the tubular heat exchanger.

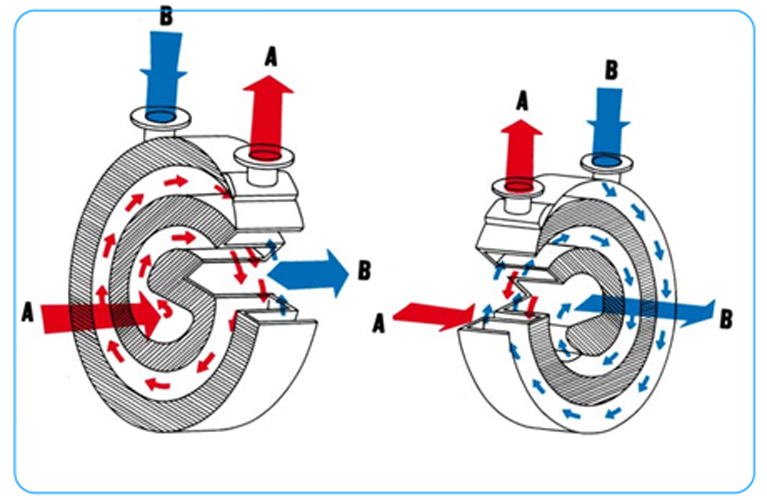

- Basic Principles :The fluid a enters at the center of the unit, flows from the inside outward along the spiral channel. At the other hand, the fluid B enters at the periphery and flows towards the center along the spiral channel. As result, the two fluid currents become counter currents entirely.

The Charecteristics of Spiral Heat Exchanger:

Effective Employment of The Heal

-

- The high heat-transferred efficiency can be achieved because the fluid currents.

- Owing to the low-temperature fluid flowing utmost outside around, there is almost no heat loss occurred so that the insulation can be omitted.

- The condition of intermixing would not take place because the channels side to each other are sealed by gasket fitted completely.

- There is a high heat-transferred effiency between the small temperature difference fluids.

Excellent Heat Transmission

-

- The higher heat-transferred coefficient can be reached because the flowing fluids in both spiral channel possess the same property to the tube side of tubular heal exchanger, and the condition of side flow in tubular heat exchanger, and the condition of side flow not in existence.

- It is easy to generate the rotary current in the contiuous curved spiral channels. Therefore, the heat-transfer rate is more superior to straight tubes.

- The rotary current possesses the function of scraping off the sedimentation solids, therefore, the fouling factor is extremely low.

Convenience for Maintenance

-

- The rotary current of spiral heat exchanger possesses the property of scraping off and spilling the sludge (solids). Even though scale stick on it, when the cross-section of the stuck part becomes smaller, the flowing speed would turns quick and brings the function of auto-cleaning into play owing to the one-way flows. Thereafter, it is unnecessary to dismantle for cleaning.

- In case there is need to take it apart for some other reasons, it is convenient for checking only to relax the screws and remove the cover, then the channels would show up entirely.

- It is not necessary to remove the cover in case of chemical cleaning.

- There is no condirion of leaks in the structure due to the unit is welded entirely.

Equipment Space

-

- High capacity of heat exchanging can be obtained, through the smallest heat-transferred area due to the high total heat-transmission coefficient.

- The shape is artful and the desigh area occupies small because the rectangular heat-transferred board is designed to be folded into small capacity.

- The equipment area is less than 1/10 if compared with that of the tubular heat exchanger.

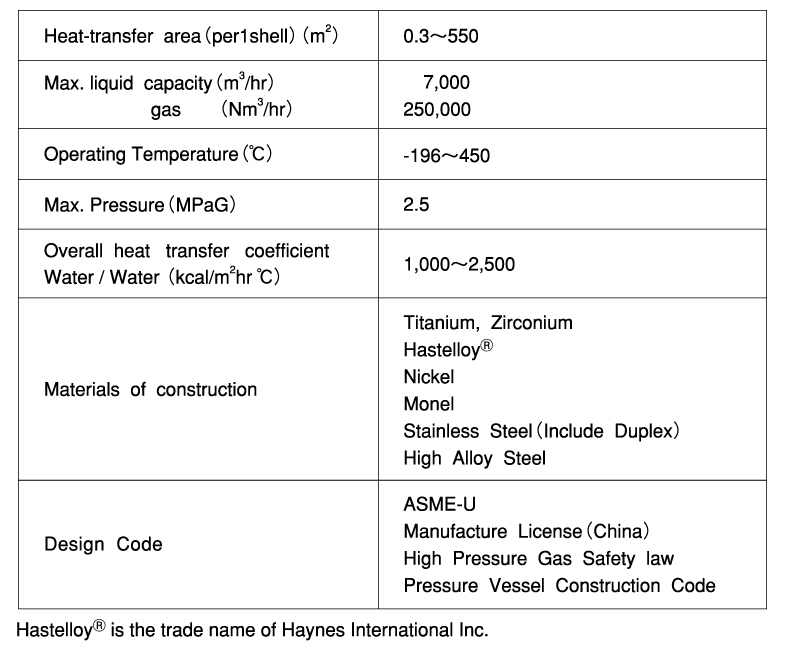

KSH Technology Data: