FORGED BODY TRUNNION MOUNTED BALL VALVES SIDE ENTRY

GWC Produces a full line of API-6D Trunnion Mounted Ball valves in both two/three Piece Forged. We Offer a full range of materials in carbon, alloy and stainless steel from general to severe in application, including Sub sea.

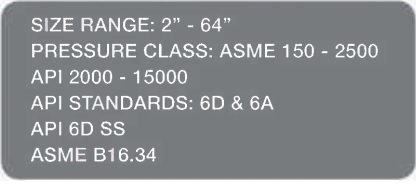

GWC ITALIA Side Entry ball valves are used in pipelines, pumping and compression stations, offshore, onshore, subsea and cryogenic as well as abrasive and high temp applications. The extensive size range and pressure class are available in a variety of materials including Carbon, Alloy & Stainless steel suitable for general to severe service conditions.

The trunnion ball valve is a form of quarter-turn valve which uses a hollow, perforated and fixed/supported ball to control flow through it. A trunnion mounted valve means that the ball is constrained by bearings and is only allowed to rotate, the majority of the hydraulic load is supported by the System constraints, resulting in low bearing pressure and no shaft fatigue. The line pressure drives the upstream seat against the stationary ball so that the line pressure forces the upstream seat onto the ball causing it to seal. The mechanical anchoring of the ball absorbs the thrust from the line pressure, preventing excess friction between the ball and seats, so even at full rated working pressure operating torque remains low. This is particularly advantageous when the ball valve is actuated because it reduces the size of the actuator and hence the overall costs of the valve actuation package. Advantages of trunnion ball design is the lower operating torque, ease of operation, minimized seat wear (Stem/ball isolation prevents side loading and wear of downstream seats improving performance and service life), superior sealing performance at both high and low pressure (a separate spring mechanism and upstream line pressure is used as the sealing against the stationary ball for low pressure and high pressure applications). The trunnion is available for all sizes and for all pressure classes but they are not suitable for throttling purposes.

FEATURES

• 2-3 PIECE BODY

• FULL AND REDUCE BORE

• TRUNNION MOUNTED

• DOUBLE BLOCK AND BLEED

• ANTI-BLOW OUT SYSTEM

• ANTI-STATIC DEVICE

• FIRESAFE TO API-607/6FA

• SPRING LOADED SEATS

• SEALANT INJECTION ON REQUEST

• NACE MR-01-75

FOR MORE INFORMATION ABOUT THE PRODUCT

PLEASE CLICK LINK BELOW

CATALOGUE.PDF